Orica Kooragang Island Ammonia

UGL provided structural, mechanical and piping services to Orica while delivering the tertiary abatement project supporting our client, Orica, on their journey to decarbonise their operations.

Orica is committed to reduce its carbon footprint in the mining, quarrying, oil and gas and construction markets in which they operate.

Details

Location

Kooragang Island, NSWStatus

CompletedSector

ResourcesExpertise

Client

Orica

Project background

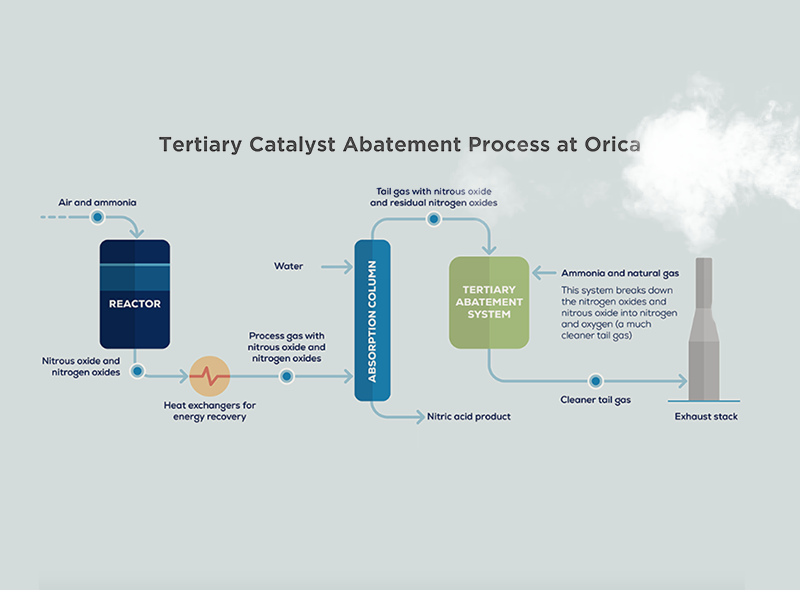

In 2019, Orica's Carseland manufacturing plant in Canada adopted the Tertiary Catalyst Abatement technology business model, and following its successful operation, it was replicated in Australia for the Kooragang Island Decarbonisation Project. The technology is designed to deliver up to 95 per cent abatement efficiency from unabated levels, reducing the site’s total greenhouse gas emissions by almost 50 per cent.

The decarbonisation project involved Orica and UGL to deliver the Tertiary Catalyst Abatement Project under UGL's Office of Federal Safety Commission (OFSC) accreditation. The work involved installing tertiary abatement technology equipment within the nitric acid plants at Orica's major hazard facility in Kooragang Island, NSW.

Challenges

UGL performed the principal contractor role, responsible for managing seven other contractors under UGL’s OFSC accreditation. Safe management of simultaneous operations during the pre-outage and outage windows was a significant risk requiring active management. The complexity of delivering a complex brownfield upgrade on a fully operational major hazard facility was a significant challenge for the UGL and Orica teams. UGL aimed to reduce the number of critical lifts (crane lifts over the operational plant), which required planning to perform this work during outage windows when possible.

Project details

Scope of work

UGL provided a practical response to the delivery of our safety requirements and created an Interface Agreement that specified how the installation of tertiary abatement would be delivered safely while meeting quality standards set by Orica. This included:

- safety management of the Orica team and seven contractors that worked on this project.

- delivery of the structural, mechanical, and piping (SMP) work scope.

- scaffold platforms with complete encapsulation to keep work teams safely separated. This required constant monitoring to ensure the safe delivery of project work.

- critical and non-critical lifts were all managed by approved UGL’s Lift Plans. UGL expertise in this area was used to review and approve all lift plans for this project supplied by the crane contractor and Orica site team.

Key outcomes

UGL delivered this project under their OFSC accreditation and met Orica’s quality, schedule, and cost requirements. There were no lost time incidents on the site during the mobilisation, pre-outage, outage, and demobilisation periods for this project, which was an outstanding achievement for those involved.

UGL successfully managed the OFSC accreditation with Orica and the seven onsite contractors to deliver increased safety focus, awareness and understanding.

UGL is proud to have supported its client to reduce greenhouse gas emissions from its three nitric acid plants by at least 98%.

Our culture